Lathe machine and proper cutting tool allows you to create various workpiece by various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, parts reclamation, and glass-working.

Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices.

Any lathes operated by experienced machinist can produce three-dimensional solids of incredible complexity. With proper cutting tools and vice, the workpiece is usually held in place by either one or two centers, at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other work-holding methods include clamping the work about the axis of rotation using a chuck or collet, or to a faceplate, using clamps or dog clutch.

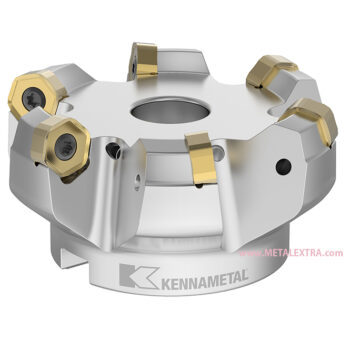

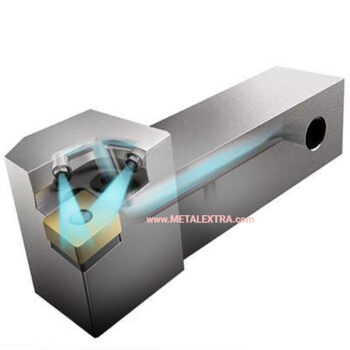

Tool holder problem in lathe operation

If your cutting tool has not been installed properly, you are likely to have improper metal cuts. So, before you start working, do not forget to check that the cutting tool is set correctly in the center of it. The trick to perfect installation is to remember to get accurate and immaculate cuts. Because of cutting metal, due to continuous friction, the head of the cutting tool often becomes too hot.

Fix it: To avoid this, pause the machine frequently. Let it cool down and then start again.

Noise and unsettling vibration?

Abruptly, you may find that your machine is not working perfectly. Don’t get panicked. This can happen when the tailstock of the lathe machine is not fixed properly. There is no certain purpose of this tailstock. Still, it needs to be locked down firmly before you begin cutting. The cut of the metal will not be proper if the tailstock remains unattached or loose.

Fix it: Examine the screws properly to tighten the tailstock. If you find them loose, do tighten them well.

The carriage stuck or improper

With time you can get a ‘stuck carriage’ in your lathe machine. Not only the carriage but also the power providing handles need to be working perfectly for the machine to run efficiently.

Fix it: It is foremost you know how to move or unstuck the carriage. Because it has particular tracks to move within. It is better to be well versed in fixing the carriage to get efficient work from the machine.

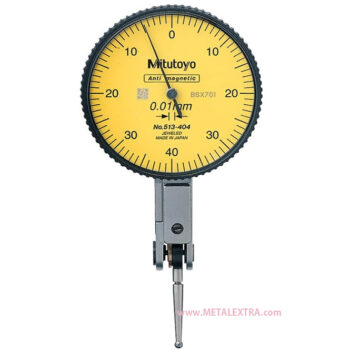

Precision graduation

These lathe machines have a dial to control the threads cut. Test the dial using various feeds and different speeds to have efficient control over the dial.

Fix it: Inspect the smoothness of handling with every speed and feed. It will give you a better feel of working along with controlling the dial. Do this at the outset of employing your equipment on the metal.

Chatter and other vibration

The vibrating problem may occur in a wood lathe for a couple of reasons. A wood lathe usually spins at 2400 to 3000 revolutions per minute. The common reason can be that your machine is not centered on the wood you are working with. So, it is a balancing problem. Having mentioned the speed, it is natural that the lathe will be thrown off balance from the imbalanced wood and it can cause vibrations.

Another reason can be the high spin speed. Slow down the spin revolution per minute to stop vibration. The piece might be thrown off if the wood vibration is high.

Fix it: Is this vibration a matter of concern? Most of the time it is minor, but it can get dangerous too. Do make sure that the wood is in the midpoint accurately to get rid of imbalance.

Awkward noise

Many lathe users have faced grinding noises in their machines. The most obvious reason for this noise is that the machines might not have been lubricated properly. Lubrication is needed in all the moving parts of a machine. If the gears, bearings, and seals are dry, lubricate those.

Fix it: Give a look at your manufacturer’s descriptions and lubricate them as per requirement. It is important to use proper lubricant for the parts. If your machine continues to make this sound, you better see your manufacturer know the cause and fix this problem.

Tear out problem?

The inside edge of the wood, on which you are working, often encounters a tear-out problem. This problem is also one that is somewhat difficult to deal with. There are several reasons for this tear-out; A common reason can be caused by the type of wood you are working with. The softer the woods are, the more tear-out you will face. So, it will be wise to choose thick woods.

Fix it: However, dull tools can also cause the tear-out problem. Thus, keep sharp tools while working. To lessen the risk of a tear-out problem choosing sharp tools will be great.

Safety hazard and prevention

Lathe machines can lead to accidents as well. Safety is a crucial key while working with any machine. To protect your eyes, nothing can be better than using safety goggles. Your clothes can get caught within the machine so you must wear proper workshop clothes.

Fix it: Clean the carriage on a regular basis to avoid metal dust on it. Use a brush to take off metal particles but be in the distance as much possible. This distance can help you avoid the direct contact of metal particles with your skin. These particles may cause scrapes and bruises.

Conclusion

That is all regarding some of the common problems and their possible solutions of lathe machines. I really hope, you will find the solutions helpful to your problem. If the problem still persists, feel free to comment.

Awalnya dipublikasikan pada9 June 2020 @ 10:44 AM