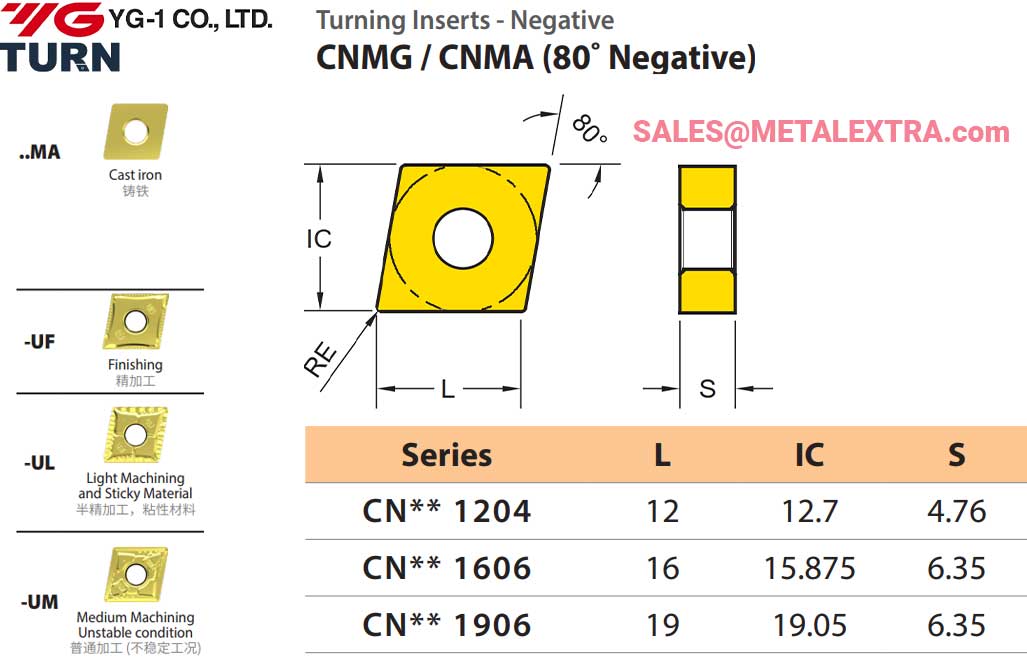

Dimension Guide YG-1 Turning Insert Negative (80˚ ISO) CNMG-UR for Roughing

Ordering Guide YG-1 Turning Insert Negative (80˚ ISO) CNMG-UR for Roughing

| |

P05 |

P10 |

P15 |

P20 |

P30 |

P20 |

| K10 K20 |

M20 |

| CNMA CNMG |

Designation |

RE |

Fn

(mm/rev.) |

Ap

(mm) |

YG1001 |

YG3010 |

YG3015 |

YG3020 |

YG3030 |

YG801 |

| Medium Machining at stable condition普通加工 (稳定工) |

CNMG 120404 – UG |

0.4 |

0.2 ~ 0.4 |

0.5 ~ 2.0 |

|

● |

|

● |

● |

|

| 0181 |

0182 |

0183 |

| CNMG 120408 – UG |

0.8 |

0.2 ~ 0.4 |

1.0 ~ 3.0 |

● |

● |

● |

● |

● |

● |

| 0337 |

0113 |

1001 |

0099 |

0139 |

0001 |

| CNMG 120412 – UG |

1.2 |

0.2 ~ 0.4 |

1.5 ~ 4.0 |

● |

● |

|

● |

● |

|

| 0685 |

0198 |

0199 |

0200 |

| CNMG 160608 – UG |

0.8 |

0.20 ~ 0.40 |

1.5 ~ 5.0 |

● |

|

|

● |

● |

|

| 1077 |

0748 |

0749 |

| CNMG 160612 – UG |

1.2 |

0.2 ~ 0.4 |

1.5 ~ 5.0 |

● |

● |

|

● |

● |

|

| 0791 |

0530 |

0508 |

0531 |

| CNMG 160616 – UG |

1.6 |

0.2 ~ 0.4 |

1.8 ~ 5.0 |

● |

● |

|

● |

● |

|

| 1229 |

0534 |

0510 |

0535 |

| CNMG 190608 – UG |

0.8 |

0.20 ~ 0.50 |

3.0 ~ 7.0 |

|

● |

|

● |

● |

|

| 0801 |

0802 |

0803 |

Cast iron and

Medium roughing

铸铁,半粗加工

|

CNMG 120404 – UC |

0.4 |

0.2 ~ 0.4 |

0.5 ~ 2.5 |

● |

● |

|

● |

● |

|

| 0096 |

0115 |

0101 |

0116 |

| CNMG 120408 – UC |

0.8 |

0.2 ~ 0.4 |

1.0 ~ 4.0 |

● |

● |

|

● |

● |

|

| 0062 |

0117 |

0102 |

0118 |

| CNMG 120412 – UC |

1.2 |

0.2 ~ 0.4 |

1.5 ~ 4.5 |

● |

● |

|

● |

● |

|

| 0088 |

0119 |

0103 |

0120 |

Roughing

粗加工

|

CNMG 120408 – UR |

0.8 |

0.3 ~ 0.5 |

1.0 ~ 4.0 |

● |

● |

|

● |

● |

|

| 1050 |

0195 |

0196 |

0197 |

| CNMG 120412 – UR |

1.2 |

0.3 ~ 0.5 |

1.5 ~ 5.0 |

● |

● |

|

● |

● |

● |

| 1051 |

0204 |

0205 |

0206 |

0004 |

| CNMG 120416 – UR |

1.6 |

0.3 ~ 0.5 |

2.0 ~ 5.0 |

|

● |

|

● |

● |

|

| 0707 |

0623 |

0847 |

| CNMG 160608 – UR |

0.8 |

0.3 ~ 0.5 |

1.0 ~ 5.0 |

|

|

|

● |

● |

|

| 0750 |

0751 |

| CNMG 160612 – UR |

1.2 |

0.3 ~ 0.5 |

1.5 ~ 5.0 |

● |

● |

|

● |

● |

|

| 0792 |

0532 |

0509 |

0533 |

| CNMG 160616 – UR |

1.6 |

0.3 ~ 0.5 |

2.0 ~ 5.0 |

● |

● |

|

● |

● |

|

| 0676 |

0536 |

0511 |

0537 |

| CNMG 190608 – UR |

0.8 |

0.3 ~ 0.8 |

3.0 ~ 9.0 |

|

● |

|

● |

● |

|

| 0804 |

0805 |

0806 |

| CNMG 190612 – UR |

1.2 |

0.3 ~ 0.8 |

3.0 ~ 9.0 |

● |

● |

|

● |

● |

|

| 0450 |

0451 |

0698 |

0699 |

| CNMG 190616 -UR |

1.6 |

0.3 ~ 0.8 |

3.0 ~ 9.0 |

● |

● |

|

● |

● |

|

| 0480 |

0481 |

0734 |

0735 |

Application Guide YG-1 Turning Insert Negative (80˚ ISO) CNMG-UR for Roughing

| |

Vc (m/min.) |

| ISO VDI |

切削速度

Sub Group

分组 |

YG1001

Min Max |

YG3010

Min Max |

YG3015

Min Max |

YG3020

Min Max |

YG3030

Min Max |

YG801

Min Max |

YG211

Min Max |

YG213

Min Max |

YG214

Min Max |

YG100

Min Max |

YG10

Min Max |

| P |

1~5 |

Non-Alloyed Steel |

220 |

480 |

170 |

450 |

170 |

410 |

180 |

380 |

150 |

350 |

120 |

200 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

| 6~9 |

Low-Alloyed Steel |

220 |

420 |

180 |

380 |

130 |

360 |

110 |

350 |

90 |

300 |

70 |

200 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

| 10~11 |

High-Alloyed Steel |

– |

– |

100 |

330 |

80 |

310 |

60 |

300 |

70 |

250 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

| M |

12~13 |

Ferritic & Martensitic |

– |

– |

– |

– |

– |

– |

– |

– |

120 |

230 |

– |

– |

130 |

230 |

110 |

180 |

80 |

150 |

– |

– |

– |

– |

| 14 |

Austenitic Stainless Steel 奥氏体不锈钢 |

– |

– |

– |

– |

– |

– |

– |

– |

80 |

200 |

– |

– |

100 |

200 |

40 |

130 |

30 |

120 |

– |

– |

– |

– |

| K |

15~16 |

Grey Cast Iron |

170 |

420 |

120 |

300 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

| 17~18 |

Nodular Cast Iron |

120 |

410 |

120 |

280 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

| N 21~30 |

Non-Ferrous Metals (Al) |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

3,501,200 |

250 |

800 |

| S 31~37 |

Superalloys &Titanium |

– |

– |

– |

– |

– |

– |

– |

– |

35 |

80 |

– |

– |

30 |

90 |

20 |

40 |

20 |

40 |

– |

– |

– |

– |

| H 38~41 |

Hard Materials |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |