Since its founding in 1918, Kitagawa has established its own technological capabilities whilst supporting Japan’s global manufacturing industry. Kitagawa is the specialist in three core businesses: the production and development of innovative casting and machining techniques of metal raw materials; supplying power chucks and numerically controlled (NC) rotary tables to the global machine tool industry; constructing custom-made concrete and recycling plants as well as providing construction machinery for various projects, including bridge erection and self-propelled multi-floor parking.

Kitagawa has built a reliable reputation by consistently providing exceptional technology across a variety of manufacturing industries.

The first division specialises in synthetic metals; tackling material development with various casting methods and machining.

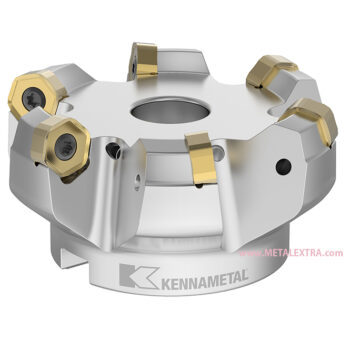

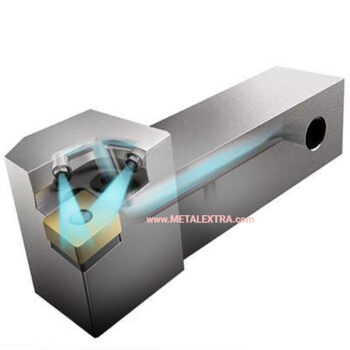

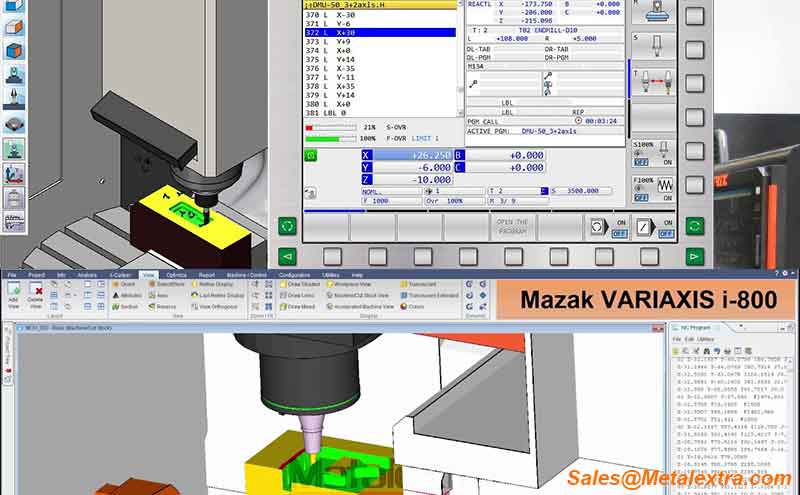

We manufacture and supply standard power chucks, rotary cylinders, NC rotary tables, vices, work grippers, as well as other peripheral equipment for machine tools such as turning centres and vertical machining centres. The Kitagawa standard power chuck is well regarded by our customers for its quality and longevity. The Kitagawa power chuck currently accounts for 60% of Japan’s domestic market share and has a well-supported network of sales and service offices throughout the global market.

Kitagawa also manufacture components for the Japanese automotive industry; from the original casting to the finished product. This integral production requirement demonstrates Kitagawa’s vast experience in improving and maximising the effectiveness and efficiency of work holding products for the automotive industry.

This allows us to provide customised products and solutions to the world, optimising our customers’ manufacturing processes. Our specialised team of numbers of engineers are dedicated to customising products and pride themselves on their meticulous attention from the preliminary meeting until the product is delivered. Kitagawa can plan your entire machining line; our engineers can recommend combinations of chucks and NC rotary tables in addition to individual products, providing our customers with an optimised solution based on their production facilities and work components.

We will continue to work together to develop and offer high-quality products and provide sufficient after-sales service and support.

Another of Kitagawa’s divisions supplies Power Chucks and NC Rotary tables among other accessories to the global machine tool industry. Lastly, Kitagawa’s industrial machinery division supplies tower cranes for building construction, concrete mixing plants and multi-story car parking.

Looking to the future, Kitagawa aims to increase the competitiveness and availability of its products on a global scale, without sacrificing our dedication to maintaining the highest quality production plants throughout the world.