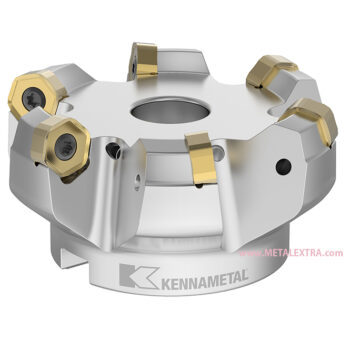

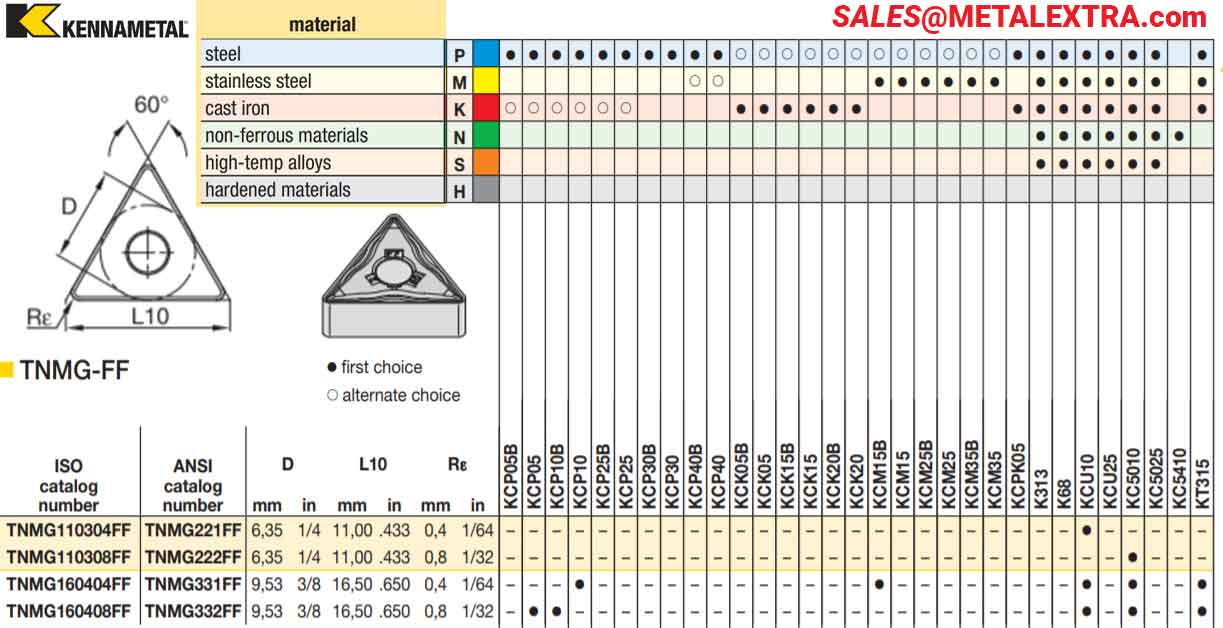

KENNAMETAL Carbide Insert KC5010 Kenloc™ TNMG-FF merupakan pilihan pertama dalam aplikasi bubut material cast iron dan Tool Steel yang memiliki nilai hardness hingga 60 HRC.WIDIA Carbide Turning Insert Victory™ TNMG-FF telah dirancang khusus untuk pergantian kinerja tinggi dengan setiap holder bertipe T-Style seperti Kenloc™ dari Kennametal maupun merek lain. Sangat baik untuk pemesinan sebagian besar cast iron, bahan non-ferro seperti plastik Nylon, dan paduan super dalam kondisi stabil. Ini juga melakukan pengerjaan dengan baik pada material chipping yang diperkeras dan pendek. Tingkat produktivitas tertinggi dicapai karena kinerja yang dioptimalkan di setiap bahan dan aplikasi yang dirancang khusus, namun harap perhatikan holder dan kode produknya apakah berbasis ISO atau ANSI.

KENNAMETAL Carbide Insert KC5010 Kenloc™ TNMG-FF merupakan solusi alat pisau bubut yang sesuai dengan standar ISO yang berlaku secara universal pada semua pengerjaan bubut. Ada 7 grade material yangb bisa dipilih; KCP10B, KCM15B, KCU10, KCP10, KCP05, KT315, KC5010 yang merupakan Coated carbide. Secara umum setiap grade merupakan solusi alat pisau bubut yang sesuai dengan standar ISO dan dicoating dengan teknologi pelapisan alumina CVD. Lapisan titanium-aluminium-nitrida (TiAlN), merupakan lapisan senyawa kimia dari tiga elemen titanium, aluminium, dan nitrogen. Ketebalan lapisan antara 1-4 mikrometer (μm). Dibandingkan dengan cutting tool yang tidak dilapisi, pelapisan TiAlN meningkatkan masa pakai hingga sepuluh kali lebih lama daripada material insert tanpa coating.

Sejak 1938, Kennametal Inc. Pennsylvania Amerika Serikat, menawarkan solusi metalworking presisi seperti; toolholders, boring bars, milling cutters, indexable drills, carbide drills, carbide endmills, taps dan lainnya. Pastikan kehandalan dan keaslian produk KENNAMETAL dengan membeli di METALEXTRA.COM.

Fitur KENNAMETAL Carbide Insert KC5010 Kenloc™ TNMG-FF:

-

Dilapis coating CVD dengan 7 grade material yang bisa dipilih untuk besi dan baja umum hingga stainless steel dengan nilai kekerasan hingga 60 HRC.

-

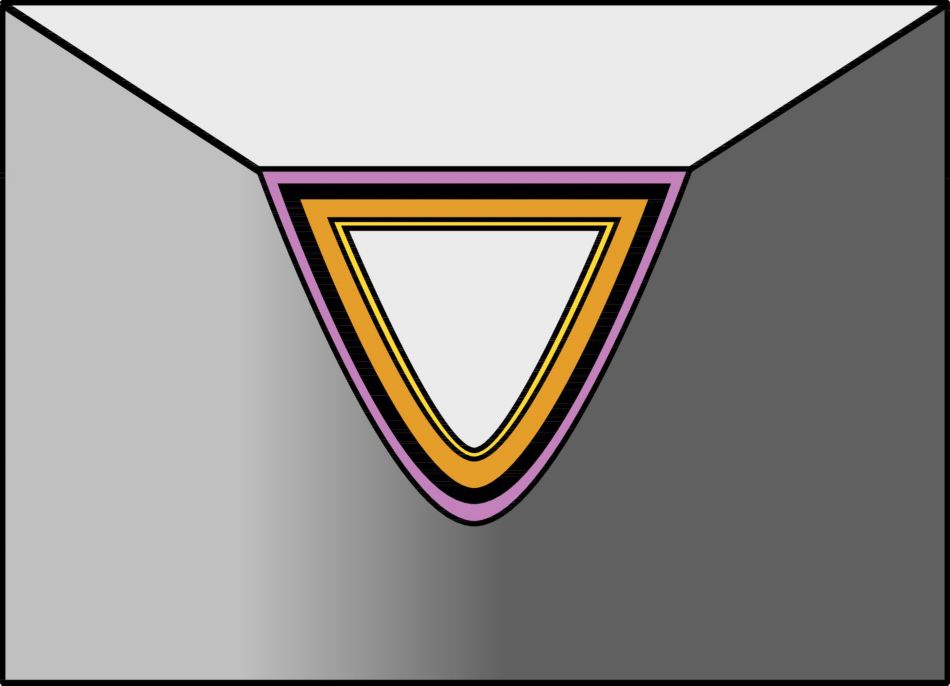

Positive Rake, desain chip breaker yang sangat positif akan memastikan pemecahan chip yang ideal dengan kedalaman pemotongan kecil standar ISO cocok dijepit dengan setiap holder tipe T.

-

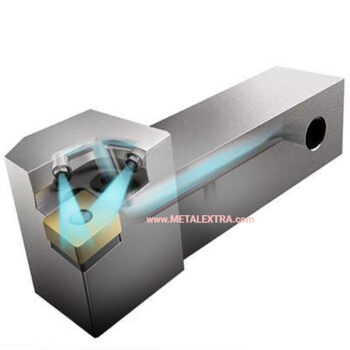

Solusi produktif dengan teknologi cutting geometry agresif dan kombinasi dengan cairan pendingin presisi tinggi untuk pemecahan chip yang sangat baik

-

Pemesinan yang andal dan aman juga ditentukan oleh feed rate pemakanan dan kecepatan putar bubut, bahkan dalam aplikasi roughing dengan pemakanan awal

- Tiap kotak cartridge insert KENNAMETAL isinya 10 pcs

Harap dicatat:

Gambar hanya untuk tujuan representasi. Produk mungkin berbeda dari yang ditunjukkan di atas. Diskon% dibulatkan ke Bilangan bulat terdekat. Harga bisa berubah sewaktu-waktu seiring dengan perubahan nilai tukar valuta asing dan program promosi. Untuk lebih jelas silahkan hubungi: sales@Metalextra.com