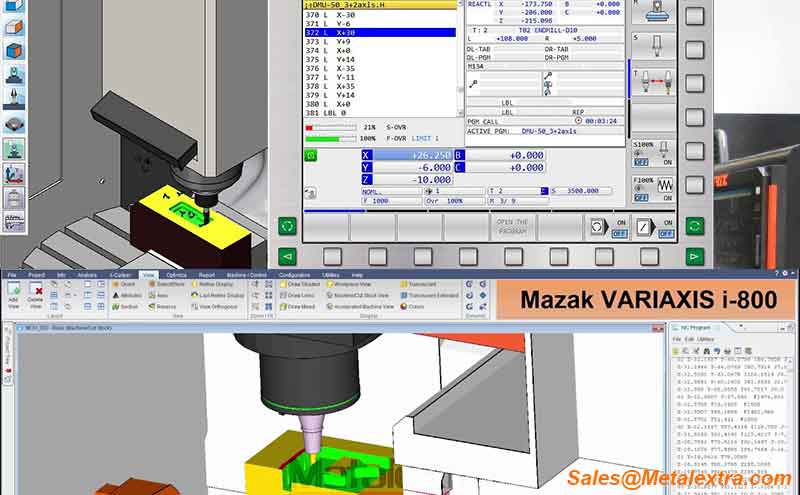

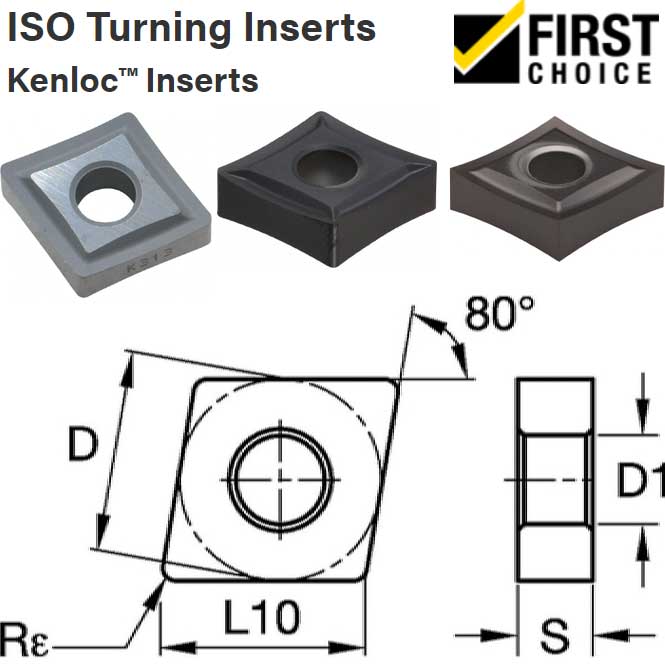

Kami merangkum informasi dari setiap prinsipal dan inovator teknik dalam menemukan dan menganalisis masalah dengan keahlian tertentu yang diperlukan. Dengan kata lain, tantangan Anda dalam menghubungkan manusia dengan bidang keahlian yang mungkin membutuhkan solusi terbaru. Jika Anda ingin berkontribusi pada artikel maupun ingin memilki direct link dan update, silahkan hubungi kami di Sales@Metalextra.com