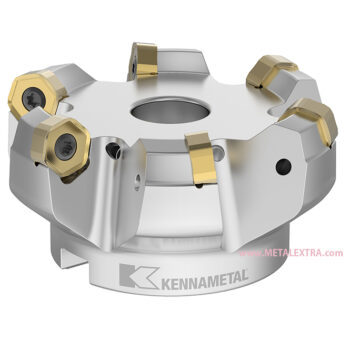

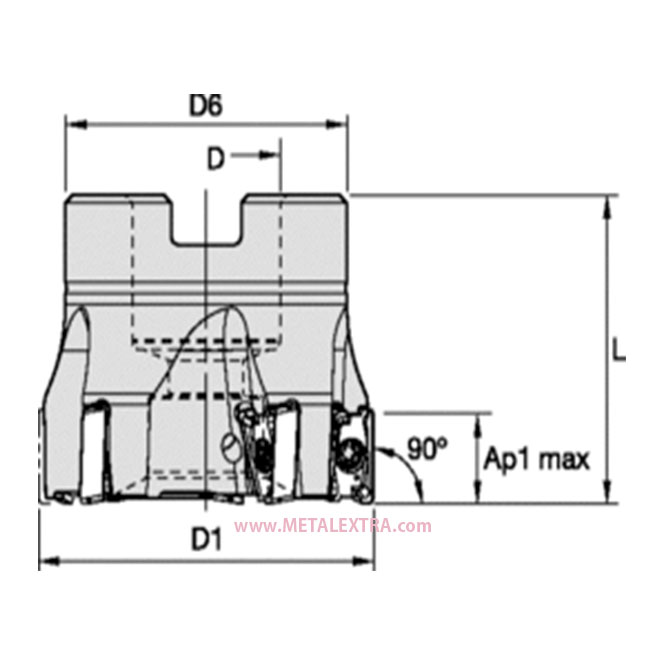

KENNAMETAL Shell Mills 4-11™ menawarkan solusi machining dengan metode Shoulder milling dengan passing pemotongan yang dalam. Mata potong freiss ini menggunakan insert yang bisa dilepas dan diganti yang sudah didesain dengan pemotong tepi panjang dan pemotong giling sisi dan wajah. Jika dibandingkan dengan desain standar ISO face shoulder dari desain konvensional seringkali hanya mampu memotong pahatan “dangkal” 90 derajat.

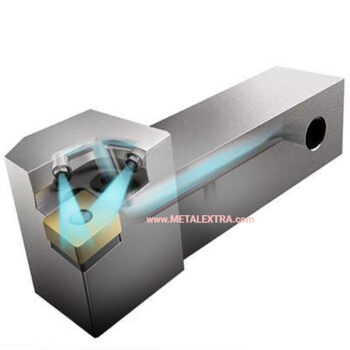

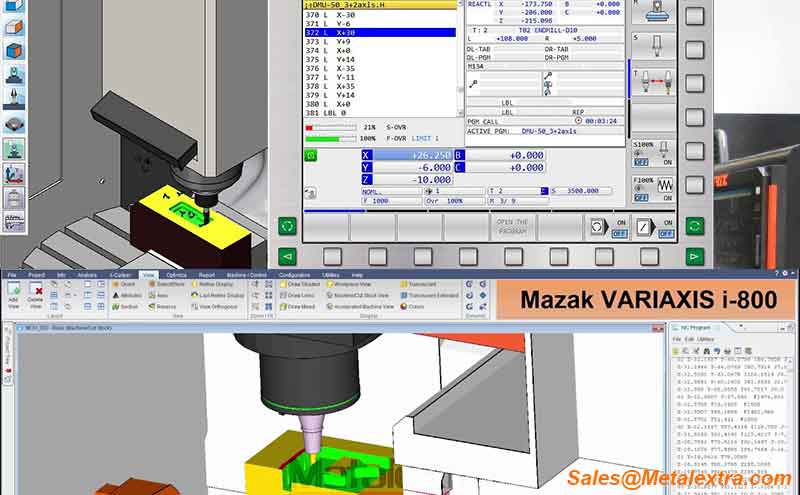

Tantangan dengan aplikasi milling deep cut dan Step-Down adalah sebagian besar alat potong meninggalkan bekas guratan potong pada setiap passing lintasan yang diambilnya. Menghasilkan penyelesaian dinding yang tidak mulus atau berkualitas rendah, hal ini malah memboroskan waktu lagi untuk proses pemolesan abrasif di akhir proses. Menerapkan KENNAMETAL Shell Mills 4-11™ dengan kedalaman potong 6,5 mm atau kurang, akan menghasilkan lapisan permukaan yang mulus dan menghilangkan proses poles finishing dengan alat tambahan. KENNAMETAL Shell Mills 4-11™ akan menghemat waktu Anda dan mengurangi biaya produksi Anda. KENNAMETAL Shell Mills 4-11™ terdiri dari pemotong Screw-on, end mill, dan shell mill dengan pendingin internal juga insert dua sisi yang tahan lama dengan empat ujung mata potong pisau.

Kennametal juga menawarkan beragam pilihan Insert end dan solid end mill Carbide yang terbukti memberikan solusi yang baik untuk aplikasi shoulder machinig yang lebih agresif dengan waktu yang lebih cepat. Karena ada banyak pilihan model, maka anda sebagai engineer maupun operator milling CNC untuk mempertimbangkan persyaratan operasional dengan hati-hati untuk membuat pilihan yang optimal. Banyak shoulder milling cutter yang tersedia merupakan pemotong universal, dan dapat digunakan secara menguntungkan untuk membuat pahatan. Namun, hanya Kennametal yang mampu memberikan alternatif yang baik untuk menghadapi aplikasi milling pada material yang solid seperti stainless steel, casting iron, maupun high-temp alloys terutama ketika dibutuhkan proses pemotongan permukaan yang kerap membelokkan secara aksial atau untuk proses pemakanan dengan face mill secara vertikal.

Fitur KENNAMETAL Shell Mills 4-11™:

- Hasil permukaan yang murni, dan menghilangkan penggunaan alat abrasif polishing tambahan sekaligus menghemat waktu Anda, dan mengurangi biaya produksi Anda.

- Kedalaman potong hingga 11mm / 0,433 “.

- Dinding superior selesai pada kedalaman pemotongan 6,5 / 0,255 “mm.

- Indexable insert bisa dilepas dan bongkar pasang sesuai kebutuhan machinig

- Cocok untuk semua aplikasi roughing hingga finishing.

- Pilihan yang tepat untuk aplikasi machining CNC stepping down atau passing pemakanan menurun.

- Bisa mencapai pasing pemakanan material hingga 11mm depth of cut.