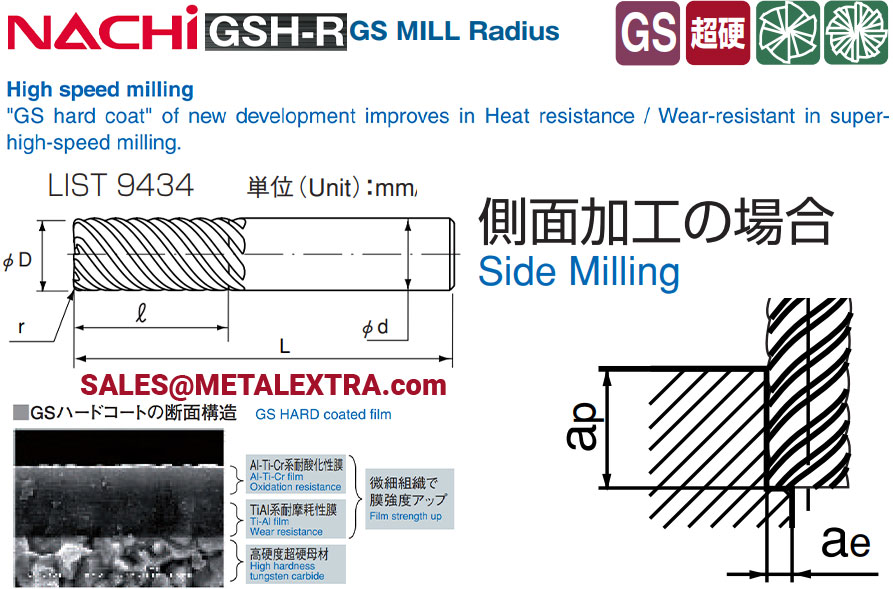

Dimension of NACHI GS MILL Hard Radius ø6mm – ø20mm GSH-R LIST9434:

High-speed processing of high-hardness materials With the newly developed ultra-aluminum-rich Al-Ti-Cr laminated coating “GS Hard Coat” Increased oxidation resistance at 1100 ° C more than 3 times as much as before Improved heat resistance and wear resistance in ultra-high speed machining The surface roughness of the surface layer is very smooth like the conventional GS coat and reduces frictional resistance during cutting.

Ordering Guide of NACHI GS MILL Hard Radius ø6mm – ø20mm GSH-R LIST9434:

商品記号

CODE |

外径

D |

コーナー半径

r |

刃長

R |

全長

L |

シャンク径

d |

刃数

NT |

| GSH6060SF-R02 |

6 |

0.2 |

13 |

50 |

6 |

6 |

| GSH6060SF-R05 |

6 |

0.5 |

13 |

50 |

6 |

6 |

| GSH6060SF-R10 |

6 |

1 |

13 |

50 |

6 |

6 |

| GSH6080SF-R02 |

8 |

0.2 |

19 |

60 |

8 |

6 |

| GSH6080SF-R05 |

8 |

0.5 |

19 |

60 |

8 |

6 |

| GSH6080SF-R10 |

8 |

1 |

19 |

60 |

8 |

6 |

| GSH6100SF-R05 |

10 |

0.5 |

22 |

70 |

10 |

6 |

| GSH6100SF-R10 |

10 |

1 |

22 |

70 |

10 |

6 |

| GSH6100SF-R15 |

10 |

1.5 |

22 |

70 |

10 |

6 |

| GSH6100SF-R20 |

10 |

2 |

22 |

70 |

10 |

6 |

| GSH6120SF-R05 |

12 |

0.5 |

26 |

75 |

12 |

6 |

| GSH6120SF-R10 |

12 |

1 |

26 |

75 |

12 |

6 |

| GSH6120SF-R15 |

12 |

1.5 |

26 |

75 |

12 |

6 |

| GSH6120SF-R20 |

12 |

2 |

26 |

75 |

12 |

6 |

| GSH8160SF-R10 |

16 |

1 |

32 |

90 |

16 |

8 |

| GSH8160SF-R15 |

16 |

1.5 |

32 |

90 |

16 |

8 |

| GSH8160SF-R20 |

16 |

2 |

32 |

90 |

16 |

8 |

| GSH8200SF-R10 |

20 |

1 |

38 |

100 |

20 |

8 |

| GSH8200SF-R15 |

20 |

1.5 |

38 |

100 |

20 |

8 |

| GSH8200SF-R20 |

20 |

2 |

38 |

100 |

20 |

8 |

NOTE:

| 外径(mm)D |

許容差(mm)Tolerance |

| を超え Above |

以下 Up to |

| |

3 |

0~-0.015 |

| 3 |

|

0~-0.030 |

Application Guide ofNACHI GS MILL Hard Radius ø6mm – ø20mm GSH-R LIST9434:

被削材

Work Material

切削条件

Milling Conditions

外径 D

mm |

低硬度鋼 炭素鋼、合金鋼

Hardened Steels, Carbon Steels, Alloy Steels

(~35HRC) |

中硬度鋼

プレハードン鋼、ダイス鋼

Hardened Steels, Pre-Hardened Steels, Mlod Steels

(35~45HRC) |

焼入鋼 SKD61

Hardened Steels SKD61

(45~55HRC) |

焼入鋼 SKD11

Hardened Steels SKD11

(55~60HRC) |

焼入鋼 SKH51

Hardened Steels SKH51

(60~65HRC) |

回転数

Rotation

min-1 |

送り速度

Feed

mm/min |

回転数

Rotation

min-1 |

送り速度

Feed

mm/min |

回転数

Rotation

min-1 |

送り速度

Feed

mm/min |

回転数

Rotation

min-1 |

送り速度

Feed

mm/min |

回転数

Rotation

min-1 |

送り速度

Feed

mm/min |

| 1 |

48000 |

1250 |

48000 |

1250 |

48000 |

1250 |

48000 |

930 |

38000 |

700 |

| 2 |

48000 |

2850 |

48000 |

2850 |

48000 |

2850 |

36000 |

1600 |

24000 |

1000 |

| 3 |

32000 |

4900 |

32000 |

4900 |

32000 |

4900 |

24000 |

2740 |

16000 |

1700 |

| 4 |

24000 |

5200 |

24000 |

5200 |

24000 |

5200 |

18000 |

2900 |

12000 |

1800 |

| 5 |

19200 |

5800 |

19200 |

5800 |

19200 |

5800 |

14300 |

3200 |

9600 |

2000 |

| 6 |

16000 |

5800 |

16000 |

5800 |

16000 |

5800 |

12000 |

3200 |

8000 |

2000 |

| 8 |

12000 |

5800 |

12000 |

5800 |

12000 |

5800 |

9000 |

3200 |

6000 |

2000 |

| 10 |

9600 |

5800 |

9600 |

5800 |

9600 |

5800 |

7200 |

3200 |

4800 |

2000 |

| 12 |

8000 |

5800 |

8000 |

5800 |

8000 |

5800 |

6000 |

3200 |

4000 |

2000 |

| 16 |

6000 |

5400 |

6000 |

5400 |

6000 |

5400 |

4500 |

3000 |

3000 |

1900 |

| 20 |

4800 |

4600 |

4800 |

4600 |

4800 |

4600 |

3600 |

2580 |

2400 |

1600 |

基準切込み量

Depth of Cut |

1~1.5D |

| 0.1D |

0.05D |

0.02D |

0.01D |

- Use highly rigid machining center.

- Recommend dry process in case of high speed milling.

- Adjust milling condition when unusual vibration, different sound occur by cutting.

- ワークや機械により振動や異音が発生するときは、 状況に応じて切削条件を変更してください。