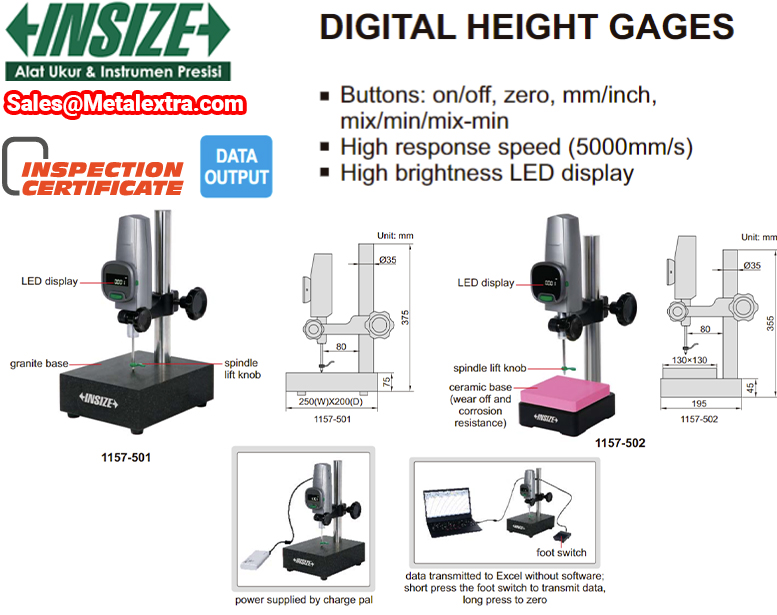

Tentang INSIZE Co. Ltd.

INSIZE Tools menawarkan lebih dari 1.000 item varian alat ukur, alat uji dan alat bantu kerja inspeksi presisi dengan standar DIN, ISO, ANSI dan JIS, serta alat khusus. Didirikan pada tahun 1995, produk alat kerja berlabel INSIZE diproduksi di Suzhou, Jiangsu dan merupakan salah satu merek terkemuka yang terdaftar dengan berbagai paten terdaftar di China. Sedangkan, produk dengan label INSIZE PLUS sendiri diproduksi oleh INSIZE JERMAN dan dilkalibrasi sesuai dengan standard akurasi tertinggi. Oleh karena itu berdasarkan standar industri, sertifikasi dan negeri asal pabrik perakitan, INSIZE memiliki dua label yaitu:

Factory standard quality and made in China and Taiwan

Factory standard quality and made in China and Taiwan

Testing laboratory, premium quality that are made in Switzerland, Germany and Italy.

Testing laboratory, premium quality that are made in Switzerland, Germany and Italy.

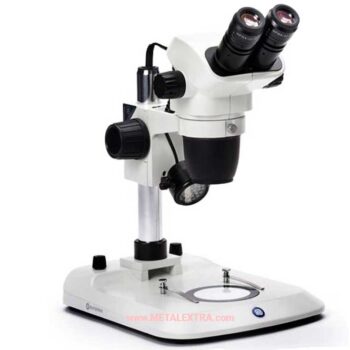

Tentu saja, INSIZE menggunakan komponen global dan jalur rantai produksi atau supply chain yang beragam. Mikroskop yang berlabel INSIZE memiliki label asal negeri Taiwan ataupun China tetapi menggunakan LED dari Jepang dan sensor dari Italia, dan begitu juga sebaliknya dengan produk berlogo INSIZE PLUS. Kombinasi ini dimaksudkan agar anda memperoleh alat kerja yang sesuai kualitasnya dan terjangkau harganya.

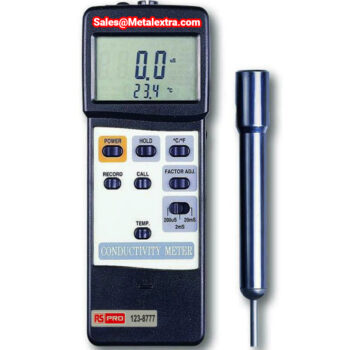

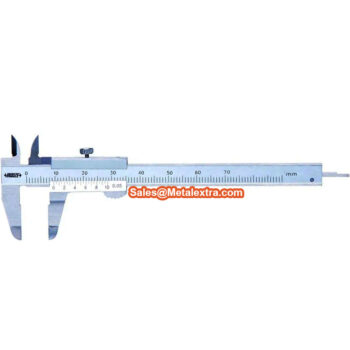

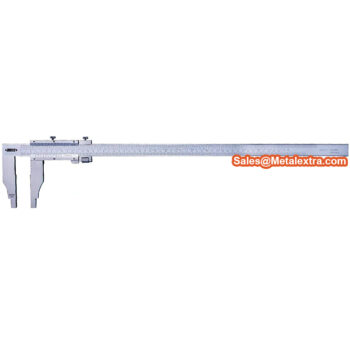

Dalam praktik pertukangan, teknik dan di bidang fisika dan produksi manufaktur, pengukuran merupakan aktivitas vital yang membandingkan kuantitas fisik benda dan peristiwa dunia nyata. Alat ukur adalah alat yang digunakan untuk mengukur suatu benda atau kejadian. Semua pengukur dapat mengalami berbagai kesalahan peralatan. Jika Anda membutuhkan toleransi dan budget yang minim, mungkin merk INSIZE bisa menjadi solusi untuk kebutuhan Anda.

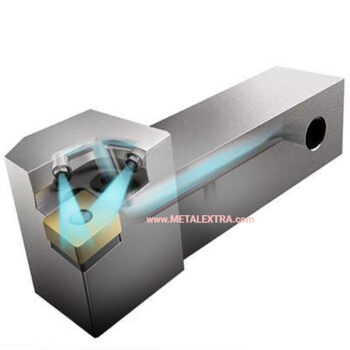

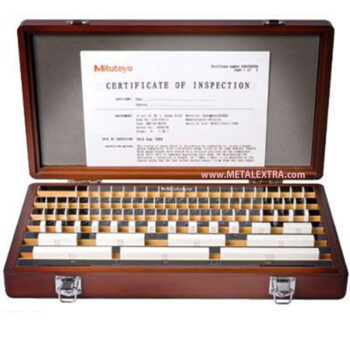

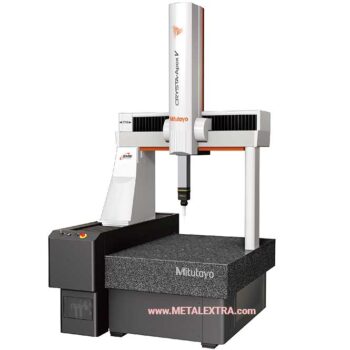

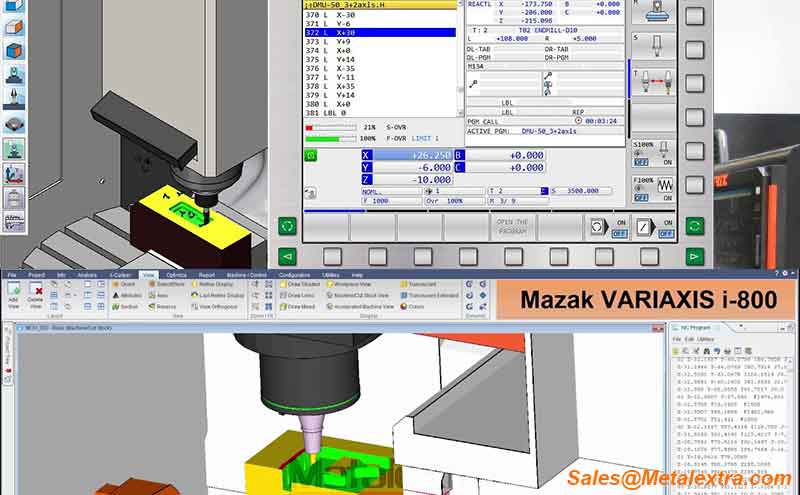

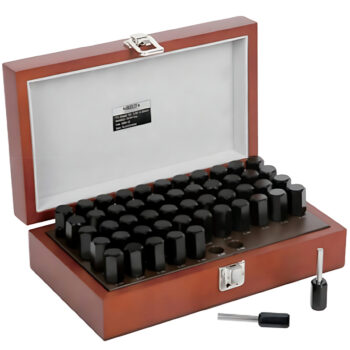

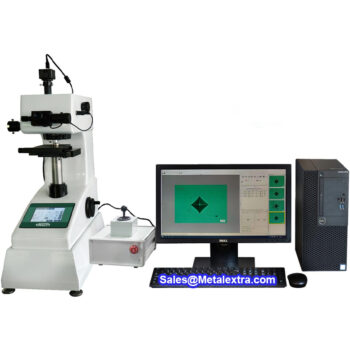

Ada beragam alat kerja yang ditawarkan INSIZE. Dari alat referensi ukur sederhana seperti Blok pengukur jarak antara permukaan paralel hingga untuk memverifikasi keakuratan mikrometer dan pengukur lainnya, setiap alat ukur telah dikalibrasi dari pabrikan agar siap pakai. Unit Dial dan Digital Indikator dari INSIZE bisa digunakan untuk mengukur jarak dan sudut kecil, memastikan keakuratan manufaktur untuk kontrol kualitas, menyetel mesin untuk produksi, atau membuat pengukuran yang tepat untuk berbagai aplikasi. Durometer mengukur elastisitas bahan maupun persiapan titik kerja pada mesin bor dan mesin milling selama persiapan material.

Pastikan kehandalan dan keaslian produk INSIZE dengan membeli di METALEXTRA.COM

.