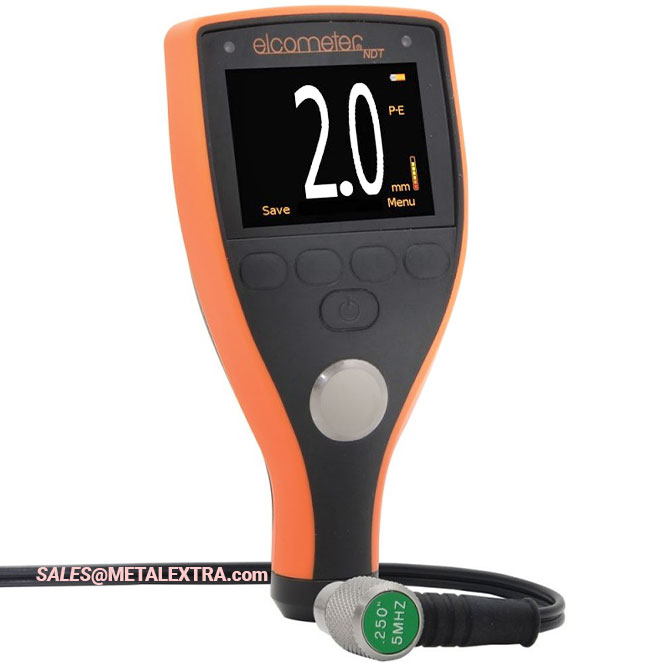

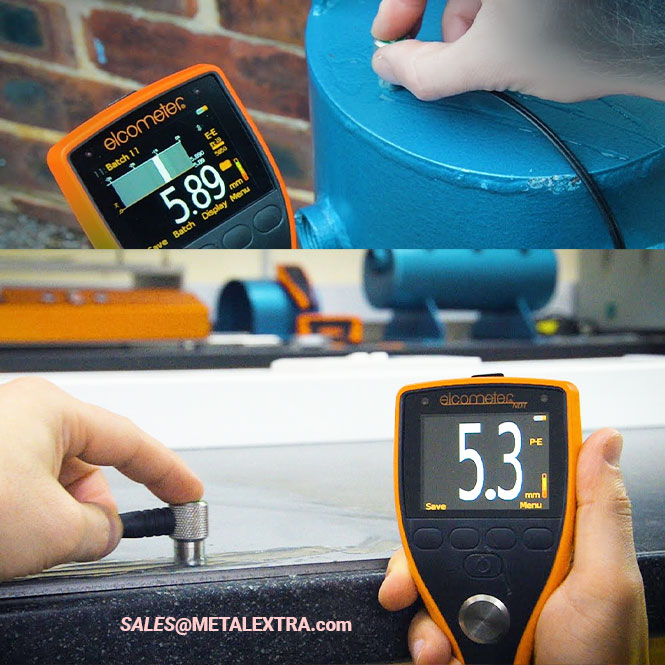

ELCOMETER Ultrasonic Material Thickness Gauge MTG4-TXC :

| Model |

MTG2 |

MTG4 |

| Thickness Range |

Pulsed Echo |

0.63 – 500mm (0.025 – 19.999″) |

| Echo-Echo ThruPaint™ |

– |

2.54 – 20mm (0.100-0.787″) |

| Accuracy |

Pulsed Echo |

0.63 – 19.99mm: ±0.1mm; 20 – 500mm: ±0.5% (0.025 – 0.787″: ±0.004″; 0.788 – 20″: ±0.5%) |

| Echo-Echo ThruPaint™ |

– |

±0.1mm (±0.004″) |

| Velocity Range |

1250 – 10,000m/s (0.0492 – 0.3937in/ps) |

| Resolution |

0.1mm (0.01″) |

| Measurement Rate |

4 Hz (4 readings per second) |

| Operating Temperature |

-10 to 50°C(14to 122°F) |

| Power Supply |

2 x AA batteries |

| Battery Life |

Approximately 15 hours |

| Gauge Weight |

210g (7.4oz) including batteries, without transducer |

| Gauge Dimensions |

145x73x 37mm (5.7 x 2.87 x 1.46″) without transducer |

Order Guide ELCOMETER Ultrasonic Material Thickness Gauge MTG4-TXC:

STANDARDS ASTM E797, EN 14127, EN15317

1 5MHz 1/4″ right angle transducer supplied

2 Internet connection required

3 The Elcometer MTG range is extendable within 60 days from date of purchase, free of charge to two years

4 Dependent on the material being measured and the transducer being used

5 On steel

6 Approximate battery life, when in Continuous Reading Mode at a reading rate of 4Hz. Rechargeable batteries may differ.

Accesories ELCOMETER Ultrasonic Material Thickness Gauge MTG4-TXC:

|

Calibration Standard Sets

|

| Part Number |

Description |

|

T920CALSTD-SET1

|

Calibration Standard Set;

Nominal Thickness; 2-30mm (0.08-1.18″)1

Comprising of nominal thickness; 2, 5, 10, 15, 20, 25 & 30mm (0.08, 0.20, 0.39, 0.59, 0.79, 0.98 & 1.18″), complete with holder and calibration certificate. |

|

T920CALSTD-SET2

|

Calibration Standard Set;

Nominal Thickness; 40 – 100mm (1.57 – 3.94″)1

Comprising of nominal thickness; 40, 50, 60, 70, 80, 90 & 100mm (1.57, 1.97, 2.36, 2.76, 3.15, 3.54 & 3.94″), complete with holder and calibration certificate |

|

T920CALSTD-HLD

|

Calibration Holder;

for thicknesses up to 100mm (3.94″)

|

|

|

|

|

Individual Calibration Standards

|

| Part Number |

Nominal Thickness (mm)

|

Nominal Thickness (inches)1

|

|

T920CALSTD-2

|

2 |

0.078 |

|

T920CALSTD-5

|

5 |

0.196 |

|

T920CALSTD-10

|

10 |

0.393 |

|

T920CALSTD-15

|

15 |

0.590 |

|

T920CALSTD-20

|

20 |

0.787 |

|

T920CALSTD-25

|

25 |

0.984

|

|

T920CALSTD-30

|

30 |

1.181 |

|

T920CALSTD-40

|

40 |

1.574 |

|

T920CALSTD-50

|

50 |

1.966

|

|

T920CALSTD-60

|

60 |

2.362

|

|

T920CALSTD-70

|

70 |

2.755

|

|

T920CALSTD-80

|

80 |

3.149

|

|

T920CALSTD-90

|

90 |

3.543

|

|

T920CALSTD-100

|

100 |

3.937 |

|

|

|

|

|

Ultrasonic Couplant

|

|

T92015701

|

Ultrasonic Couplant; 120ml (4fl oz)

|

|

T92015701-5

|

Ultrasonic Couplant; 120ml (4fl oz), Pack of 5 Bottles

|

|

T92024034-7

|

Ultrasonic Couplant; 300ml (10fl oz)

|

|

T92024034-8

|

Ultrasonic Couplant; 500ml (17fl oz)

|

|

T92024034-3

|

Ultrasonic Couplant; 3.8l (1 US Gallon)

|

|

T92024034-9

|

High Temperature Couplant 371°C (700°F); 60ml (2fl oz)

|

|

T92024034-10

|

High Temperature Couplant 371°C (700°F); 60ml (2fl oz), Pack of 2

|

|

|

|

|

Transducer Adaptor

These adaptors allow single & dual element, ‘non-intelligent’ and other transducers with lemoconnectors from Elcometer NDT and other manufacturers, to be used with the MTG & PTG product range.

|

|

Part Number

|

Description

|

|

T92024911 Dual Element2

|

Transducer Adaptor

|

1 Imperial values for information purposes only. Calibration standards are manufactured and measured in millimeters.

2 This adaptor allows dual element, ‘non-intelligent’ and other transducers with Lemo Connectors from Elcometer and other manufacturers to be used with the MTG product range.

Material velocity test Chart for ELCOMETER Ultrasonic Material Thickness Gauge MTG2:

|

Elcometer Material Number

|

Material Description

(Chemical Symbol/Grouping) |

Material Name

|

Sound Velocity

(m/sec) |

Sound Velocity

(in/μsec) |

Source of value

NPL = National Physical Laboratory

ASNT = The American Society for Non destructive testing

Industry = Industry knowledge |

| 1 |

Fe |

Iron (soft)

|

5960

|

0.235

|

NPL

|

| 2 |

Fe

|

Iron Cast

|

4990

|

0.196

|

NPL

|

| 3 |

Al

|

Aluminium

(7075-T6)

|

6350

|

0.250

|

ASNT

|

| 4 |

Ti

|

Titanium

|

6100

|

0.240

|

ASNT

|

| 5 |

Mg

|

Magnesium

|

5790

|

0.228

|

ASNT

|

| 6 |

Ni

|

Nickel

|

5630

|

0.222

|

ASNT

|

| 7 |

W

|

Tungsten

|

5180

|

0.204

|

ASNT

|

| 8 |

Cu

|

Copper

|

4660

|

0.183

|

ASNT

|

| 9 |

Zn

|

Zinc

|

4190

|

0.165

|

NPL

|

| 10 |

Ag

|

Silver

|

3600

|

0.142

|

Industry

|

| 11 |

Sn

|

Tin

|

3380

|

0.133

|

NPL

|

| 12 |

Pt

|

Platinum

|

3260

|

0.128

|

NPL

|

| 13 |

Au

|

Gold

|

3240

|

0.128

|

NPL

|

| 14 |

Cd

|

Cadmium

|

2780

|

0.109

|

NPL

|

| 15 |

Bi

|

Bismuth

|

2180

|

0.086

|

Industry

|

| 16 |

Pb

|

Lead

|

2160

|

0.085

|

ASNT

|

| 17 |

Cobalt-chromium Alloy

|

Stellite

|

6990

|

0.275

|

Industry

|

| 18 |

Iron Alloy

|

Steel (Carbon 1018)

|

5920

|

0.233

|

Industry

|

| 19 |

Iron Alloy

|

Steel (Alloy 4340)

|

5850

|

0.230

|

Industry

|

| 20 |

Nickel-chromium Alloy

|

Inconel (625)

|

5820

|

0.229

|

Industry

|

| 21 |

Silver Alloy

|

Stainless Steel,

(Austentic 304)

|

5660

|

0.233

|

ASNT

|

| 22 |

Copper Alloy

|

Constantan

|

5180

|

0.204

|

NPL

|

| 23 |

Non-metal

|

German Silver

|

4760

|

0.187

|

Industry

|

| 24 |

Non-metal

|

Brass (Naval)

|

4430

|

0.174

|

ASNT

|

| 25 |

Non-metal

|

Glass (Quartz)

|

5930

|

0.233

|

ASNT

|

| 26 |

Non-metal

|

Glass (Crown)

|

5660

|

0.223

|

NPL

|

| 27 |

Non-metal

|

Glass (Flint)

|

5260

|

0.207

|

NPL

|

| 28 |

Non-metal

|

Porcelain

|

5840

|

0.230

|

Industry

|

| 29 |

Non-metal

|

Plexiglas

|

2760

|

0.109

|

Industry

|

| 30 |

Non-metal

|

Glass Fibre

|

2740

|

0.108

|

Industry

|

| 31 |

Non-metal

|

Nylon

|

2680

|

0.106

|

NPL

|

| 32 |

Non-metal

|

Epoxy Resin

|

2540

|

0.100

|

Industry

|

| 33 |

Non-metal

|

Polystyrene

|

2350

|

0.093

|

NPL

|

| 34 |

Non-metal

|

PVC

|

2330

|

0.092

|

NPL

|

| 35 |

Non-metal

|

Rubber (Butyl)

|

1830

|

0.072

|

Industry

|

| 36 |

Non-metal

|

Rubber (Natural)

|

1600

|

0.063

|

NPL

|

| 37 |

Non-metal

|

Polyurethane

|

1780

|

0.070

|

Industry

|

| 38 |

Non-metal

|

Teflon

|

1400

|

0.055

|

NPL

|

| 39 |

Non-metal

|

Water

|

1490

|

0.059

|

ASNT

|