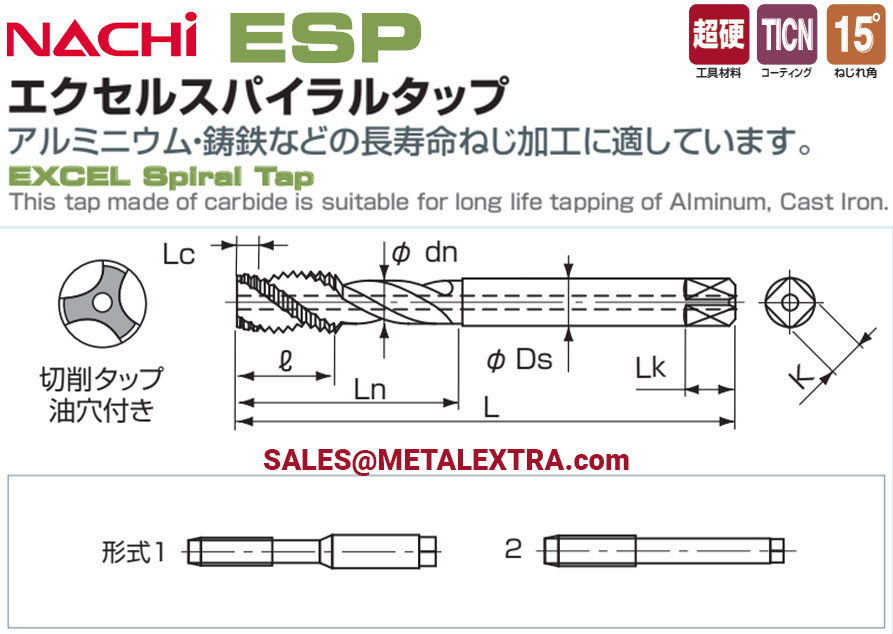

Dimension of NACHI Point Tap STPO 6868 M2 – M24:

Order Guide NACHI Point Tap STPO 6868 M2 – M24 (in mm) :

| Product No.記号 |

Thread Size

呼び |

TAP Limit

等級 |

|

食付(P)

Lc (P) |

全長

L |

ねじ長

ℓ |

Flutes

溝数 |

Ds

シャンク径 |

Ln

首下長さ |

首径

dn |

Type

形式 |

| 2M0.4R |

M2 X 0.4 |

REG |

P1 |

5 |

40 |

9 |

2 |

3 |

15 |

2.1* |

1 |

| 2M0.4R+1 |

REG+1 |

P2 |

| 2.5M0.45R |

M2.5 X 0.45 |

REG |

P2 |

5 |

44 |

10 |

2 |

3 |

16 |

2.7* |

1 |

| 2.5M0.45R+1 |

REG+1 |

P3 |

| 2.6M0.45R |

M2.6 X 0.45 |

REG |

P2 |

5 |

44 |

10 |

2 |

3 |

16 |

2.7* |

1 |

| 2.6M0.45R+1 |

REG+1 |

P3 |

| 3M0.5R |

M3 X 0.5 |

REG |

P2 |

5 |

46 |

11 |

3 |

4 |

18 |

2.4 |

2 |

| 3M0.5R+1 |

REG+1 |

P3 |

| 3.5M0.6R |

M3.5 X 0.6 |

REG |

P2 |

5 |

48 |

13 |

3 |

4 |

18 |

2.8 |

2 |

| 3.5M0.6R+1 |

REG+1 |

P3 |

| 4M0.7R |

M4 X 0.7 |

REG |

P2 |

5 |

52 |

13 |

3 |

5 |

20 |

3.1 |

2 |

| 4M0.7R+1 |

REG+1 |

P3 |

| 5M0.8R |

M5 X 0.8 |

REG |

P2 |

5 |

60 |

16 |

3 |

5.5 |

22 |

4 |

2 |

| 5M0.8R+1 |

REG+1 |

P3 |

| 6M1R |

M6 X 1 |

REG |

P2 |

5 |

62 |

17 |

3 |

6 |

28 |

4.8 |

2 |

| 6M1R+1 |

REG+1 |

P3 |

| 6M0.75R |

M6 X 0.75 |

REG |

P2 |

5 |

62 |

14 |

3 |

6 |

28 |

4.8 |

2 |

| 6M0.75R+1 |

REG+1 |

P3 |

| 7M1R |

M7 X 1 |

REG |

P2 |

5 |

65 |

17 |

3 |

6.2 |

– |

– |

3 |

| 7M1R+1 |

REG+1 |

P3 |

| 8M1.25R |

M8 X 1.25 |

REG |

P3 |

5 |

70 |

22 |

3 |

6.2 |

– |

– |

3 |

| 8M1.25R+1 |

REG+1 |

P4 |

| 8M1R |

M8 X 1 |

REG |

P2 |

5 |

70 |

17 |

3 |

6.2 |

– |

– |

3 |

| 8M1R+1 |

REG+1 |

P3 |

| 8M1R+2 |

REG+2 |

P4 |

| 10M1.5R |

M10 X 1.5 |

REG |

P3 |

5 |

75 |

27 |

3 |

7 |

– |

– |

3 |

| 10M1.5R+1 |

REG+1 |

P4 |

| 10M1.25R |

M10 X 1.25 |

REG |

P3 |

5 |

75 |

22 |

3 |

7 |

– |

– |

3 |

| 10M1.25R+1 |

REG+1 |

P4 |

| 10M1R |

M10 X 1 |

REG |

P2 |

5 |

75 |

17 |

3 |

7 |

– |

– |

3 |

| 10M1R+1 |

REG+1 |

P3 |

| 10M1R+2 |

REG+2 |

P4 |

| 12M1.75R |

M12 X 1.75 |

REG |

P4 |

5 |

82 |

32 |

3 |

8.5 |

– |

– |

3 |

| 12M1.75R+1 |

REG+1 |

P5 |

| 12M1.5R |

M12 X 1.5 |

REG |

P3 |

5 |

82 |

28 |

3 |

8.5 |

– |

– |

3 |

| 12M1.5R+1 |

REG+1 |

P4 |

| 12M1.25R |

M12 X 1.25 |

REG |

P4 |

5 |

82 |

23 |

3 |

8.5 |

– |

– |

3 |

| 12M1.25R+1 |

REG+1 |

P5 |

| 14M2R |

M14 X 2 |

REG |

P4 |

5 |

88 |

32 |

3 |

10.5 |

– |

– |

3 |

| 14M2R+1 |

REG+1 |

P5 |

| 14M1.5R |

M14 X 1.5 |

REG |

P3 |

5 |

88 |

28 |

3 |

10.5 |

– |

– |

3 |

| 14M1.5R+1 |

REG+1 |

P4 |

| 16M2R |

M16 X 2 |

REG |

P4 |

5 |

95 |

32 |

3 |

12.5 |

– |

– |

3 |

| 16M2R+1 |

REG+1 |

P5 |

| 16M1.5R |

M16 X 1.5 |

REG |

P3 |

5 |

95 |

28 |

3 |

12.5 |

– |

– |

3 |

| 16M1.5R+1 |

REG+1 |

P4 |

| 18M2.5R |

M18 X 2.5 |

REG |

P4 |

5 |

100 |

37.5 |

3 |

14 |

– |

– |

3 |

| 18M2.5R+1 |

REG+1 |

P5 |

| 18M1.5R |

M18 X 1.5 |

REG |

P4 |

5 |

100 |

28 |

3 |

14 |

– |

– |

3 |

| 18M1.5R+1 |

REG+1 |

P5 |

| 20M2.5R |

M20 X 2.5 |

REG |

P4 |

5 |

105 |

37.5 |

3 |

15 |

– |

– |

3 |

| 20M2.5R+1 |

REG+1 |

P5 |

| 20M1.5R |

M20 X 1.5 |

REG |

P4 |

5 |

105 |

28 |

3 |

15 |

– |

– |

3 |

| 20M1.5R+1 |

REG+1 |

P5 |

| 22M2.5R |

M22 X 2.5 |

REG |

P4 |

5 |

115 |

37.5 |

3 |

17 |

– |

– |

3 |

| 22M2.5R+1 |

REG+1 |

P5 |

| 22M1.5R |

M22 X 1.5 |

REG |

P4 |

5 |

115 |

28 |

3 |

17 |

– |

– |

3 |

| 22M1.5R+1 |

REG+1 |

P5 |

| 24M3R |

M24 X 3 |

REG |

P4 |

5 |

120 |

45 |

3 |

19 |

– |

– |

3 |

| 24M3R+1 |

REG+1 |

P5 |

| 24M1.5R |

M24 X 1.5 |

REG |

P4 |

5 |

120 |

31 |

3 |

19 |

– |

– |

3 |

| 24M1.5R+1 |

REG+1 |

P5 |

*:呼び径<首径です。めねじ加工深さが深い場合、ねじ長以上入れると折損の危険があります。

*: Thread Size < Neck diameter (dn) When depth of cutting a female thread is deep, if putting the screw length or more in length, there is a risk of breakage.

形式 1 ~ 2 は突出しセンタ Type 1 ~ 2 with External Centre

Application NACHI Point Tap STPO 6868 M2 – M24:

| Work Materials |

一般構造用鋼

SS Structural Steel |

低炭素鋼

S15C Low Carbon Steel |

中炭素鋼

S40C Medium Carbon Steel |

高炭素鋼

S50C High Carbon Steel |

合金鋼

SCM, SCr Alloy Steel |

高硬度鋼

Hardened Steel |

ステンレス鋼

SUS Stainless Steel |

鋳鉄

FC Cast Iron |

ダクタイル

鋳鉄

FCD Ductile Cast Iron |

アルミニウム

合金

AC, ADC Aluminum Alloy |

| — 200HB |

— 200HB |

— 200HB |

— 200HB |

— 200HB |

20 — 30HRC |

30 — 40HRC |

|

|

|

|

| STSP |

Selection chart 選定 |

o |

o |

◎ |

o |

o |

o |

– |

– |

– |

o |

o |

| MSH (m/min) Cutting Speed 切削速度 |

5—15 |

5—15 |

5—15 |

5—15 |

5—15 |

5—8 |

– |

– |

– |

5—15 |

10 — 20 |

| STPO |

Selection chart 選定 |

o |

o |

◎ |

o |

o |

o |

– |

– |

– |

o |

o |

| MSH (m/min) Cutting Speed 切削速度 |

6 — 20 |

6 — 20 |

6 — 20 |

6 — 20 |

6 — 20 |

5— 10 |

– |

– |

– |

6 — 20 |

10 — 20 |

| 推奨切削油剤 Cutting Fluids |

Sulfochlorinated Oil Water soluble Oil |

Water soluble Oil |

Attention on using the cutting condition tables

1. 表中の数値は一般的な基準であり、 ご使用条件により切削条件を変更してください。

2. 表中の数値はねじの深さ 2Dc(ねじの呼び径の 2 倍)が基準です。

1. These are general cutting condition, and may be altered by your conditions.

2. These conditions are for thread depth of 2 × Dc.