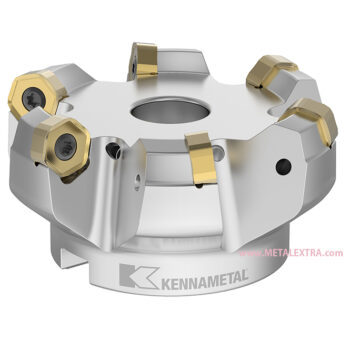

KENNAMETAL Stellram Shell Mill Cutters 7792VXD09 menawarkan solusi machining dengan metode face milling dengan passing pemotongan yang dalam dengan pilihan diameter ⌀1,5 Inch – ⌀2 Inch. Mata pisau frais ini cocok dengan 8 pilihan pisau insert yang bisa dilepas dan diganti yang sudah didesain dengan pemotong tepi panjang dan pemotong giling sisi dan wajah. Stellram® high-feed face mill ini memastikan gaya potong sebagian besar diarahkan ke arah aksial, hubungan antara cutting edge dan benda kerja paling stabil, menghasilkan tingkat umpan tinggi dan masa pakai alat yang konsisten.

Seri facemill pisau frais 7792 dari KENNAMETAL ini telah dirancang untuk aplikasi penggilingan umpan tinggi dengan generasi permukaan yang unggul. Pemotong KENNAMETAL Stellram Shell Mill Cutters 7792VXD09 dirancang untuk berbagai aplikasi yang mampu memproses semua bahan, termasuk besi baja, baja tahan karat, besi cor, dan paduan aluminium bersuhu tinggi. Harga yang tertera disini merupakan harga referensi untuk KENNAMETAL High-Feed Milling Cutters 7792VXD09 berkode ISO C7792VXD09-A2.00Z5R, 2″ Cut Diam, 0.059″ Max Depth, 3/4″ Arbor Hole, 1.574″.

Sejak 1938, Kennametal Inc. Pennsylvania Amerika Serikat, menawarkan solusi metalworking presisi seperti; toolholders, boring bars, milling cutters, indexable drills, carbide drills, carbide endmills, taps dan lainnya. Pastikan kehandalan dan keaslian produk KENNAMETAL dengan membeli di METALEXTRA.COM.

Fitur KENNAMETAL Stellram Shell Mill Cutters 7792VXD09 ⌀1,5 Inch – ⌀2 Inch:

-

Pemotong pitch ultra-halus tersedia untuk meningkatkan laju pemotongan material, terutama pada paduan suhu tinggi seperti logam High Temperature Alloy (HTA) dan Titanium 30-40 HRC.

-

Desain positif untuk mendukung gaya potong yang lebih rendah dan penggunaan overhang yang lama.

-

Kemampuan machining dengan metode ramping dan terjun milling dengan 8 jenis insert yang bisa dipilih. INSERT Dijual TERPISAH!

-

Pemotong umpan tinggi 7792VX adalah solusi luar biasa untuk mengurangi waktu siklus atau menghilangkan jumlah material maksimum dalam waktu singkat.

-

Pemotong pitch ultra-halus baru semakin meningkatkan laju penghilangan logam, terutama pada paduan suhu tinggi.

-

Desain unik dan posisi penyisipan membantu untuk mencapai tingkat umpan hingga 5x lebih tinggi daripada pemotong frais merek lain di pasar.

-

Ketika digunakan pada pemegang alat yang panjang (diperpanjang), pemotong 7792VX menyerap getaran dan sangat mengurangi ketidakstabilan dan defleksi alat.

-

Aspek maa frais finishing terintegrasi untuk peningkatan permukaan akhir: 16 Ra (1,6μ) bila digunakan pada <0,020 in / z.

7792VXP06: Maksimum ap = 0,035 “; Rentang Diameter = 0,625-1,250”

7792VXD09: Maksimum ap = 0,059 “; Rentang Diameter = 1.000–2.000”

7792VXD12: Maksimum ap = 0,098 “; Rentang Diameter = 1.250–6.300”

7792VXE16: Maksimum ap = 0,138 “; Rentang Diameter = 2.000–6.000”

Harap dicatat:

Gambar hanya untuk tujuan representasi. Produk mungkin berbeda dari yang ditunjukkan di atas. Diskon% dibulatkan ke Bilangan bulat terdekat. Harga bisa berubah sewaktu-waktu seiring dengan perubahan nilai tukar valuta asing dan program promosi. Untuk lebih jelas silahkan hubungi: Sales@Metalextra.com