Tentang Kennametal

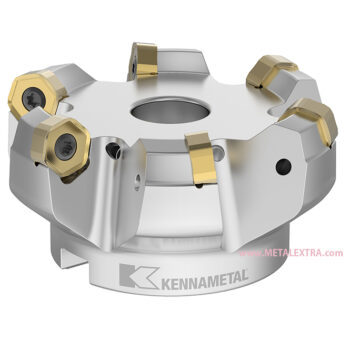

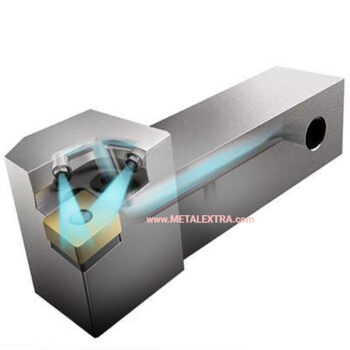

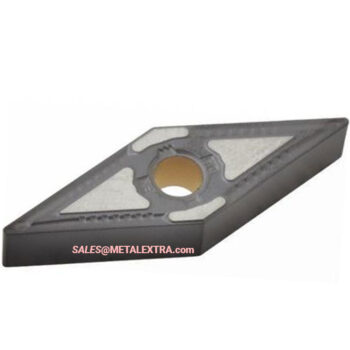

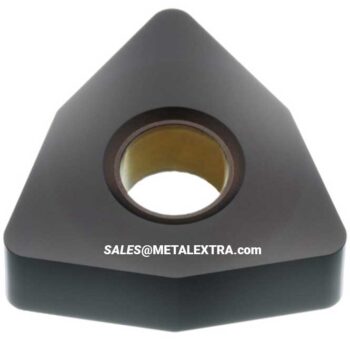

Kennametal (NYSE: KMT) merupakan inovator teknologi industri yang didirikan pada tahun 1938 oleh Philip M. McKenna di wilayah Latrobe, Pennsylvania, Amerika Serikat. Kennametal menginovasi paduan logam Tungsten-Titanium dan karbida untuk alat pemotong yang memberikan produktivitas dalam pemesinan baja. Produk Kennametal meliputi solusi metalworking, abrasive flow products, cutting tools, metallurgy, mining equipment, woodworking, fluid handling dan aksesoris terkait permesinan akurasi tinggi.

Dengan tradisi inovasi pisau industri dan coating lebih dari 80 tahun sebagai pemimpin teknologi industri, Kennametal Inc. menawarkan produktivitas kepada pelanggan melalui ilmu material, perkakas, dan solusi tahan aus. Pelanggan dari lingkup industri Dirgantara Aerospace, pekerjaan teknik pertambangan, teknik sipil, energi, teknik umum dan transportasi beralih ke Kennametal untuk meraih kualitas presisi dan efisien. Kennametal juga menjadi perusahaan terbuka yang terdaftar dengan kode saham NYSE: KMT.

Saat ini, Kennametal menghasilkan hampir USD $ 2,4 miliar pendapatan pada tahun fiskal 2019. Setiap hari ada sekitar 10.000 karyawan dan rekan Kennametal membantu pelanggan di lebih dari 60 negara agar tetap kompetitif.

Kennametal Inc. juga bermitra dengan TITANS of Industry, sebuah figur bengkel bubut dan CNC ternama di media sosial. Bersama Titan, kennametal menawarkan kelas pelatihan Aerospace Academy, sebuah platform pendidikan online yang dirancang untuk mengajar pemrogram dan teknologi operasional mesin mesin dan manufaktur kedirgantaraan bagi kesiapan generasi teknisi dari seluruh dunia.

Pastikan kehandalan dan keaslian produk KENNAMETAL dengan membeli di METALEXTRA.COM. Hubungi: sales@Metalextra.com sekarang!